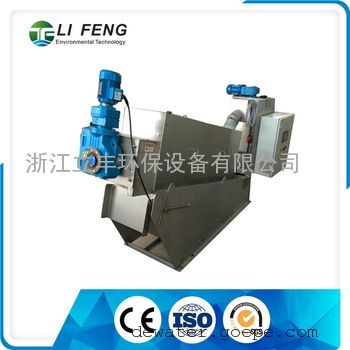

- Sludge dewater equipment

详细信息

加工定制:是 处理量:10kg T/h 品牌:立丰环保 型号:MDS131 总功率:0.24 kw 脱水率:80 % 设备容量:2500 L 周边线速度:3 m/min 无故障时间:10000 h 设备自重:1 t Material:Stainless Steel 304 Product name:Sludge Dewater Machine Size:Compact Application:Activated Sludge Dewater Motor:SUMITOMO, SEW Sludge dewater equipment-Product DescriptionSludge dewater equipment -Introduction

Multi-Disk Screw Press ( Hereinafter referred as MDS ) belongs to the screw press, it's clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of sewage plant construction. MDS using screw and the moving rings to clean itself as clog-free structure, and controlled by the PLC automatically, it's a new technology that can replace the traditional filter press like belt press and frame press, the screw speed is very low, so it cost low power and water consumption in contrast to the centrifuge, it is a cutting edge sludge dewatering machine.

Sludge dewater equipment-process

Procedure of Sludge dewater equipment

1. The sludge are transported to the flocculation tank through storage tank, and adequately mixed by the mixer.

2. After big flocs are formed, the sewage is transported to the MDS screw press.

4. Flocs moves from the thickening zone to the dewatering zone.

5. Gaps between moving rings and fixed rings narrows, and the pressure of the end plate increases dewatering,

finally the sludge cake is discharged.5. The sludge is transported out by shaftless screw conveyor.

Specification Model

Detailed Images

Name: Over All Unit

Materials: SUS304

The over all unit is made up of SUS304 material, with smooth surface. Laser cutting technical ensures the evenness of machine surface.

Name: Rings

Materials: SUS304

First of all, mechanical shaping is done to the rings by imported processing equipment from Switzerland. Then manual shaping is done to control the deviation of evenness under 0.01mm.

Name: Screw Shaft

Materials: SUS304

Tungsten carbide coating are done to the screw shaft surface. The hardness can reach HRC 71. The blade of screw shaft also get chamfering process treatment, to match with the ring.Name: Spray Tube and Nozzle

Materials: SUS304

Spray tube uses SS304 steel, mirror polished.Its nozzles can achieve well-distributed spray, can achieve solid cone effect,which is better than stainless steel nozzle suppliers

Case Study

Sludge Dewatering in Petrochemical Industry Model Type MDS413 Water

content80%±5%

Project

DetailsSludge Type: 70%chemical sludge+30% biosludge

Sludge Concentration : 2.10%

Sludge Flow Rate : 18.3m3/h

Ds Throughput : 143g/kg-DS/h

Polymer Add Rate: 384g/kg DS

Cake Solid: 17%

Capture Rate: >90%

ApplicationSludge Dewatering in textile Industry Model Type MDS311 Water

content80%±5%

Project

DetailsSludge Type: 70%chemical sludge+30% biosludge

Sludge Concentration : 1.40%

Sludge Flow Rate : 3.0m3/h

Ds Throughput : 42kg-DS/h

Polymer Add Rate: 8g/kg DS

Cake Solid: 18%

Capture Rate: >94%

Our serviceSnow Xia

Sales manger

Zhejiang Lifeng Enviromental Equipment Co.,Ltd.

Tel:+86-

Email: snow(at)dewater123.comWeb: www.dewater123.com

Alibaba: https://lfhb.en.alibaba.com

-

-

浙江立丰环保设备有限公司

叠螺式污泥脱水机.移动式污泥脱水车,平板式固液分离装置.无轴螺旋输送机,全自动加药装置,移动式磁分离污水处理站等环保装备!

内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。浙江立丰环保设备有限公司 电话:021-31596560 手机:18302187657 地址: 上海市青浦区华隆路1777号 D座 302室

扫一扫,手机浏览

扫一扫,手机浏览